Specifying Airtightness That Works

As one of the leading air tightness testers in Australia and Asia, we frequently encounter a wide range of air tightness specifications. Some are logical, some unusual, and others that, while well-intentioned, are either impractical or open to interpretation. These inconsistencies can lead to specifications that are either so lax they are easily circumvented, or so stringent that they become unachievable in practice.

Misaligned Specifications

A common clause found in Defence and commercial project specifications reads:

*”All heated and cooled spaces (excluding those defined under BCA Provision J3.1) shall be sealed per the current edition of the BCA Part J3 ‘Building Sealing’ and to a level that limits air leakage through the building envelope to a rate of:

-

-

air changes per hour (ACH) for perimeter zones of depth equal to the floor-to-ceiling height when pressurising plant is operating; and

-

ACH for the whole building when pressurising plant is not operating.”*

-

“The building envelope is defined as those components of the building that separate conditioned or habitable spaces from the exterior or non-conditioned spaces.”

The specification further requires buildings to be pressure tested to verify performance, referencing the ATTMA Technical Standard L2: Measuring Air Permeability of Building Envelopes (Non-Dwellings), Oct 2010. It’s critical to note that the BCA (2012) requirements and ATTMA L2 are fundamentally different. For instance:

- ATTMA L2 does not support deriving leakage rates in ACH at ambient pressures.

- It disallows testing while HVAC systems are operating under elevated pressure.

- It does not endorse ACH@50Pa as a valid metric for commercial buildings.

Instead, ATTMA mandates that permeability (in m³/h/m² @ 50Pa) be used for commercial and industrial project. This approach is based on envelope surface area, which ensures consistent, repeatable, and comparable results. See our article on ACH vs Permeability.

Using ACH from BCA modelling (especially under ambient or HVAC operation) raises numerous issues: What pressure does the HVAC system operate at? How airtight is the ductwork? What is the building height and location of leakage paths? These questions expose loopholes that can be exploited to generate a “pass” result even on leaky buildings using blower door testing. Here is our calculator and article that translates BCA figures to ATTMA-style permeability rates.

Compartment Testing: A Misguided Approach

We’re often asked about testing individual compartments within large commercial buildings. This is problematic. Only Level 2 ATTMA testers should undertake such testing, and compartment testing should be avoided altogether for full-building airtightness verification. Moreover, Level 1 ATTMA testers are limited to single-fan setups and buildings under 4000 m³ in volume. They’re not suited to large-scale compartment testing.

Why compartment testing is ineffective:

- It provides no meaningful insight into actual building performance.

- You can’t distinguish between internal and external leakage.

- Results are qualitative when combined with smoke, not quantitative.

- Builders may waste resources sealing internal walls that aren’t part of the external envelope.

- Only small areas are tested, violating ATTMA L2 requirements.

- Builders gain no useful experience in airtightness.

In 2012, the Australian Defence Force clarified its building sealing requirements in Clause 3.4.1 to avoid the above confusion:

“All heated and/or cooled spaces shall be sealed in accordance with the current edition of the BCA, and to the degree necessary to reduce infiltration/exfiltration to a leakage rate of ≤3 m³/h/m² of surface area (including floor area) at 50Pa.”

This aligns with ATTMA-style permeability specifications and supports consistent, reproducible testing.

Here is another interesting specification from CIBSE TM23:

Equipment Requirement

Use fan system capable of raising room pressure to 200Pa (using VSD or damper control suitable for a pressure test. Differential pressure measuring instrument and tubing to measure room pressure to ambient condition. Smoke pencils and smoke generator to identify leaks during pressure test

Test Procedures

- Seal the supply and return air duct paths to/ from the room

- Seal door openings but allow for a fan supply connection

- Seal joints between floor, walls and air grills. This includes all power outlets

- Run fan and raise the pressure of room to 100Pa (concerning ambient space outside of the room)

- If unable to achieve this pressure, then room has significant leaks. Investigate by using smoke pen/generator to identify and seal

- Once the 100Pa is achieved, switch fan OFF and shut dampers from fan to seal the room

- Record the time taken for pressure to drop from 100Pa to 60Pa. if less than 7 minutes then room seal test has failed

This is a rigorous method but is possibly unrealistic for standard construction. You may need to coat the whole building in polyurethane caulk. It may require sealing the building with polyurethane caulk. While theoretically sound, its real-world feasibility is doubtful. (A great challenge for MythBusters, perhaps!)

Unit Confusion: m³/h vs L/s

From time to time, we see leakage rates specified that are confusing m3/h with L/s. ATTMA has recommended leakage rates for different types of buildings, but if m3/h is interchanged with L/s you allow a permeability rate that is 3.6 times greater. Building envelopes are measured in m3/h, ductwork air flows and façade lab tests are measured in l/s. It’s important we don’t get them confused.

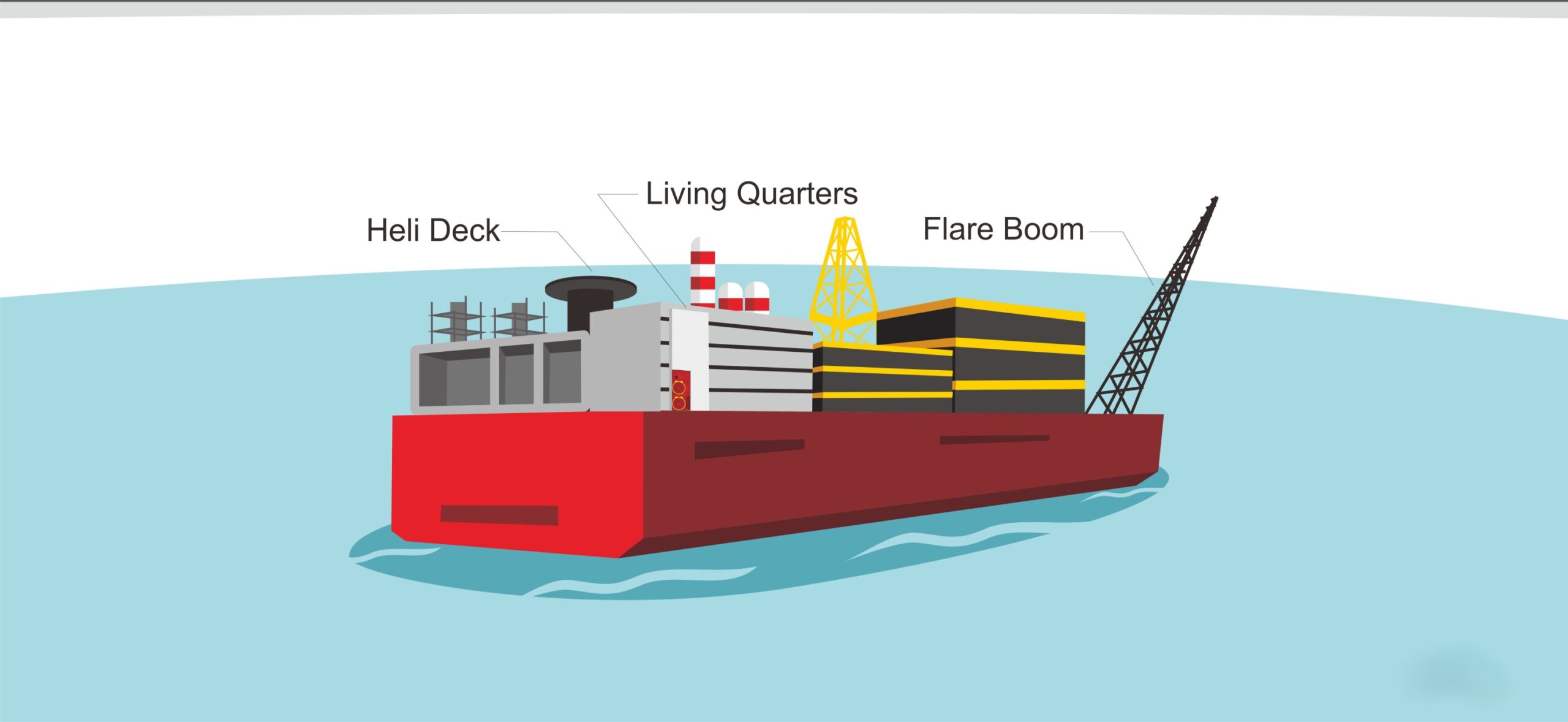

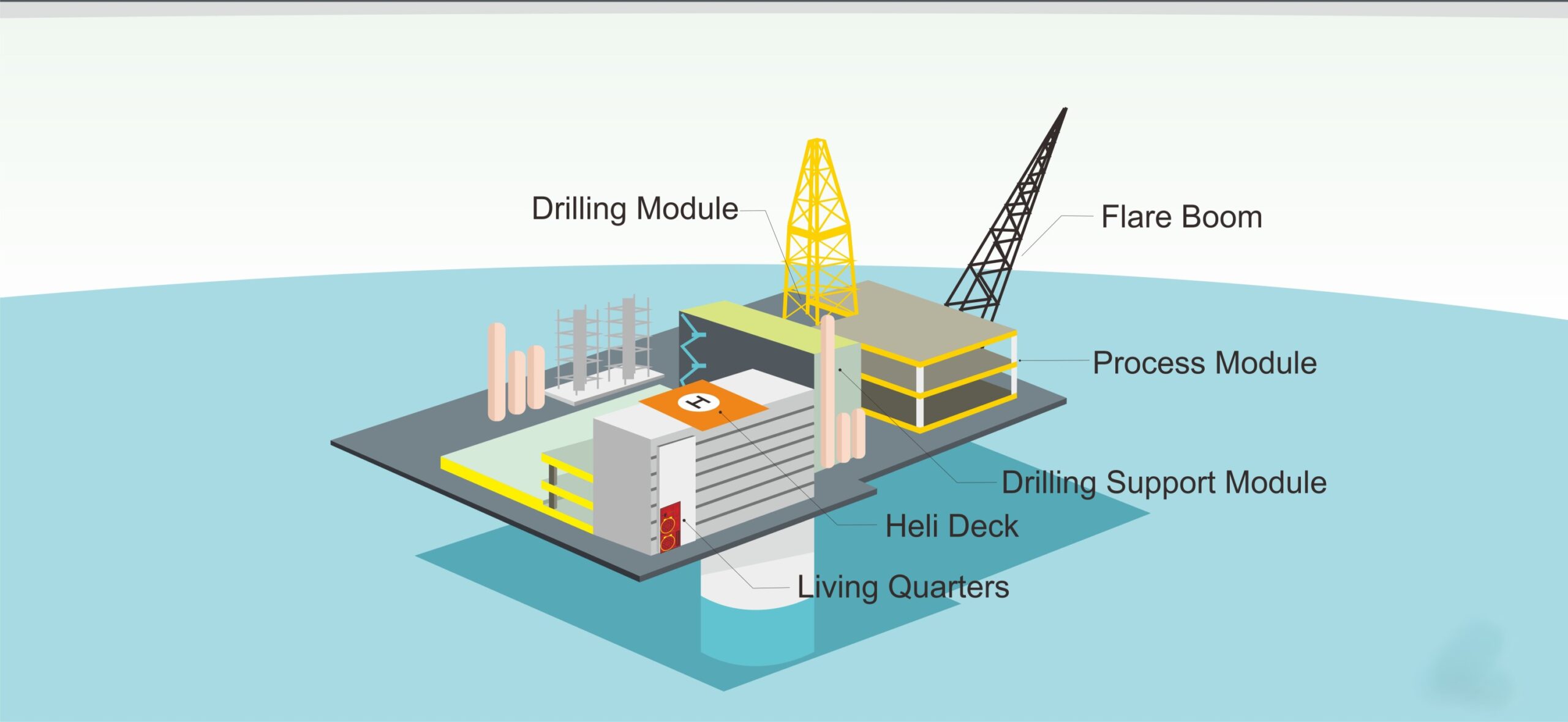

Special Cases: Oil and Gas Platforms

Special Cases: Oil and Gas Platforms

Appendix A in ATTMA on how to calculate ‘air change rate’ from measured values, specifically clause A.1.8.

“The Guidance on integrity testing for offshore installation of Temporary refuges” states that oil & gas rigs must target an ACH@50Pa for their accomoidation TR’s. In order to protect the Volume of air environment inside.

The purpose of the pressurization test is to determine the air leakage rate from the TR. This is usually converted to an air change rate measured in the non-SI units of ‘air changes per hour’ or ac/h. This measure of volume flow rate is widely accepted in the offshore industry and is more convenient than using the SI equivelant of m3/s, as in using ac/h the volume flow rate normalised by the volume of the TR. This allows the air tightness performance of different TRs with different volumes to be compared directly using the same variable.

HSE Offshore information sheet 1/2006 states that the air leakage rate is usually taken as .35ACH@50Pa, but that new build TR’s are constructed to a leakage standard of .25ACH@50Pa. However, there are many reasons why a duty holder may specify a different air leakage rate limit. For example, an accomodation platform with no production or processing functions is unlikely to be subject to high concentrations of gas or smoke products in the event of an incident, hence a larger air leakage rate may be appropriate in this case. Conversely, TR’s located close to production and process areas are more likely to be exposed to high concentrations of flammable toxic atmospheres and may require a lower limits on acceptable air leakage.

| Type of Building | Air Permeability m3/h/m2 @ 50Pa | Air Permeability m3/h/m2 @ 50Pa | Air Change Rate (ACH) @ 50Pa | Air Permeability m3/h/m2 @ 50Pa |

|---|---|---|---|---|

| Best Practice | Good | Reality | ||

| Offices | N/A | TBA | ||

| Naturally Ventilated | 3 | 7 | N/A | TBA |

| Mixed | 2.5 | 5 | N/A | TBA |

| Air Conditioned/Low Energy | 2 | 5 | N/A | TBA |

| Factories/Warehouses | 2 | 6 | N/A | TBA |

| Superstores | 1 | 5 | N/A | TBA |

| Schools | 3 | 9 | N/A | TBA |

| Hospitals | 5 | 9 | N/A | TBA |

| Museums, galleries and archival stores | 1 | 1.5 | N/A | TBA |

| Cold Stores | .2 | .35 | N/A | TBA |

| Passive House Standard | N/A | <1 | .6 | TBA |

| Passive House Retrofit | N/A | <1 | 1 | TBA |

| Oil and Gas EXISTING | N/A | N/A | .35 | TBA |

| Oil and gas NEW | N/A | N/A | .25 | TBA |

Refer to the article comparing ACH to Surface areas/permeability rate for large buildings.

Larger enclosures will be easier to pass, with oil and gas TR facilities.

Understanding ACH from an ACH@50Pa

CIBSE TM23 Explicitly states that the “divide by 20” method is for Dwellings (e.g. Residential homes) which are all very similar in size (see excerpt below). The applicability of this figure to commercial projects or facilities in the middle of an ocean is HIGHLY questionable considering the volume to surface area ratio alone. The average tall building or oil rig refuge in the middle of an ocean will be exposed to much higher winds than 4Pa.

6 Air leakage tests and infiltration rate

An air leakage test does not provide a measure of the air infiltration rate in a building, and therfore it cannot be used to estimate directly the infiltration heat loss. The test pressure of 50Pa is much higher than the pressure differences that drive infiltration due to eather conditions. A calculation can be carried out to relate the air leakage at 50Pa, say, to the air infiltration rate, but this will require some knowledge of the location and nature of the air leakage paths. If a direct measure of air infiltration is required, it involves a lengthy and complex test using tracer gases.

From a large number of measurements carried out on dweellings (and usually of similar voumes) it has been found that the air infiltration rate in air changes per hour (ACH) is approximately 1/20 of the 50Pa air leakage rate(expressed as air changes per hour rather than fabric air leakage index). The air leakage rate is defined as Q50/V, where Q50 is the leakage air flow rate at 50Pa, and V is the internal volume surrounded by the building envelope.

https://www.airah.org.au/Content_Files/EcoLibrium/2012/March%202012/2012_03_01.pdf

Infi ltration LBL 4Pa Correction Leakage rate (ACH) <.1 ACH

ltration LBL 4Pa Correction Leakage rate (ACH) <.1 ACH

-

- Average wind speeds in some oceans/land locations can be as high as 17.9km/h, which is equivalent to 4.972m/s which is an average ~15.45Pa applied wind pressure

- This criterion is more designed for residential land-based leakage rate. It is not a good idea to apply this leakage rate to a huge oil rig or a tall building, it’s not what these calculations were designed for.

Controlling the environment from outside, coming inside is of paramount importance for the safety of its personnel in the event of a gas leak or a massive disaster where smoke may engulf the whole facility.

Refer to excerpt

UNCERTAINTIES

In any qualitatively simple model such as the one developed above, the uncertainties will be large. They will be both systematic and random, as well as being hard to estimate. The size of the correction factors give an indication of some of the uncertainties (i.e., 85 10% -40%) depending on the building, in addition to the uncertainties from the LBL model itself. A good error analysis would involve a detailed simulation effort to model the distribution of buildings, climates, and other relevant factors. It should also include a large set of measured vs. predicted infiltration rates. Such an effort is beyond the scope of this report but as this

Model is used it may be possible to generate the necessary data for a good error analysis and validation.

CONCLUSIONS In this paper we have used a simplified, physical model of infiltration -the LBL model -to heuristically corroborate a simple infiltration estimation technique. The choice of model type and complexity is strongly a function of the application. A detailed description of how to choose the appropriate model for a specific application is beyond the scope of this report. (Currently, the Air Infiltration and Ventilation Centre is preparing a guide [13] to help users decide which kind of model to use.) However, it is clear that any time short-term or highly specific building specific estimates are required, the approach described herein is inadvisable. For large ensembles of annual averages or for rule-of-thumb estimates, the simplified method of indicators is appropriate. Of the two indicators used, one of them – the leakage indicator (ACH5o ) – is well known in the community. However, the climate indicator, No, the leakage-infiltration ratio is new. The way we have defined No is purely dependent upon the average climate at the site of interest. We have, however, defined a set of correction factors which use building- specific information to improve the estimate of infiltration. Future work should involve using field data to ascertain the accuracy of this method.

MAX H. SHERMAN

Energy Performance of Buildings Group, Indoor Environment Program, Applied Science Division, Lawrence Berkeley Laboratory, University of California, Berkeley, CA 94720 (U.S.A.) (Received August 6, 1986; accepted November 10, 1986; revised paper received December 12, 1986)

Air tightness testing is important, but when the building has been constructed airtight, it’s the easiest part of implementing building performance. It’s important you use a contractor who can help the building get the building to an airtight state during the construction phase. Failing a test and organising remediation works after construction is a very costly way of getting a building airtight. Having a repeatable and comparable specification is a good step in the right direction. Call Efficiency Matrix, if you need our assistance with specifications, airtightness testing and consultation during construction. We are passionate about air tightness, and empower our customers to build better. We are also the only company who has proven results from our consultancy service.

Air Tightness Consultancy