Understanding AS/NZS 5110

Understanding AS/NZS 5110 can be quite challenging and confusing. This page is dedicated to simplifying this barrier focused standard for everyone. Contact Efficiency Matrix if you have any further questions.

AS/NZS 5110 is a safety standard that is called up by AS/NZS 60598 when insulation clearances are required to be reduced, such as:

- For fire rating requirements,

- Sound proofing

- Energy efficiency

If none of the above features are needed:

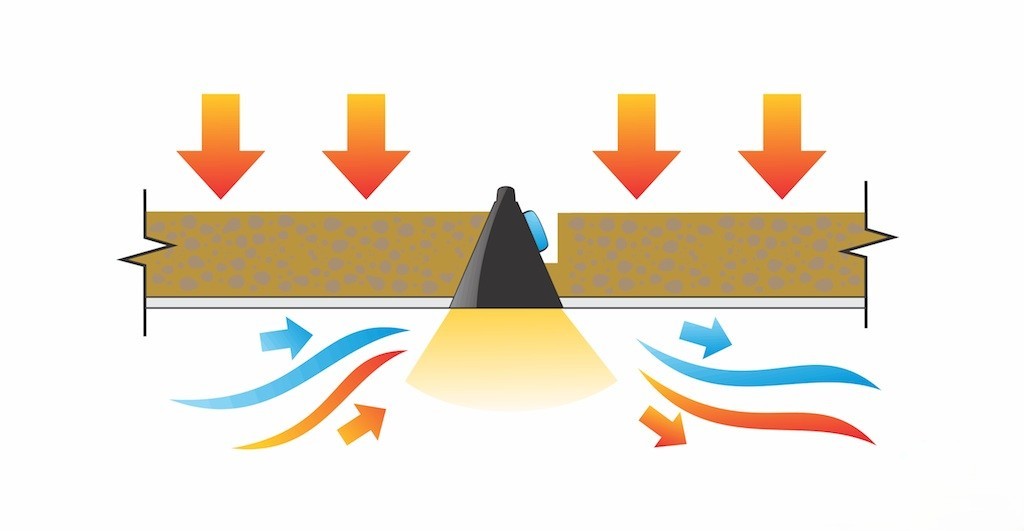

- A 200mm clearance of insulation is required from incandescent/halogen lighting, and

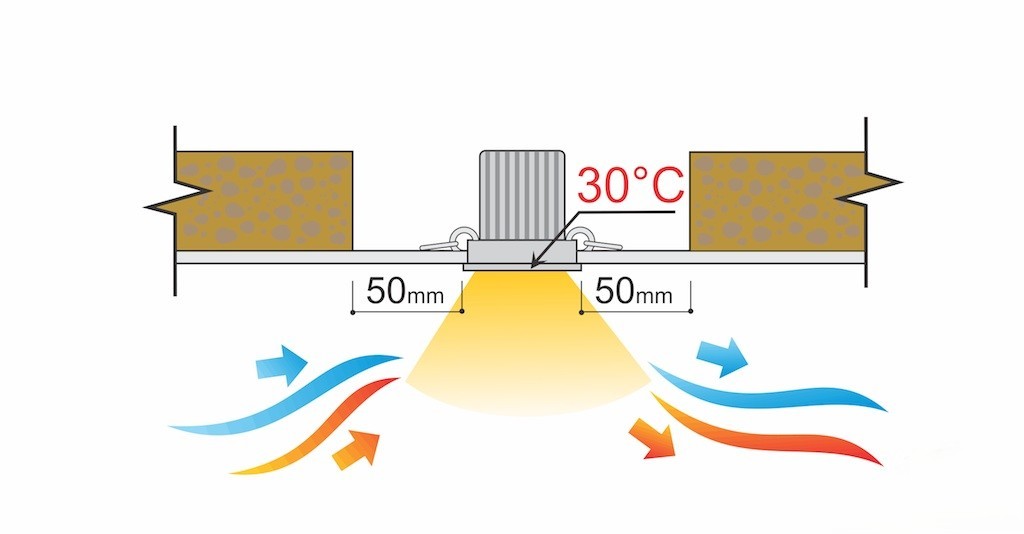

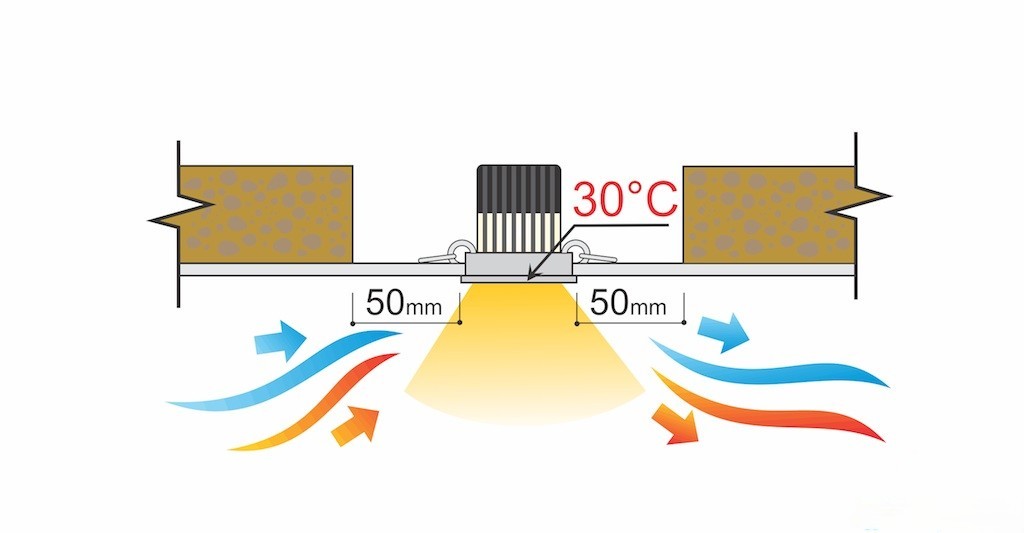

- A 50mm clearance of insulation is required from LED lighting,

and everything complies because 5110 is not required to be adhered to.

In case you need to cover your downlights for any of the three reasons listed in red above, here are the potential solutions…

Firstly, here is a good example of a solution that does not comply with AS/NZS 5110:

1. GU10 & MR16 with 50W Transformer (Iron Core or Electronic) fixed Fittings (65mm – 95mm cutout)

Status: Uncoverable

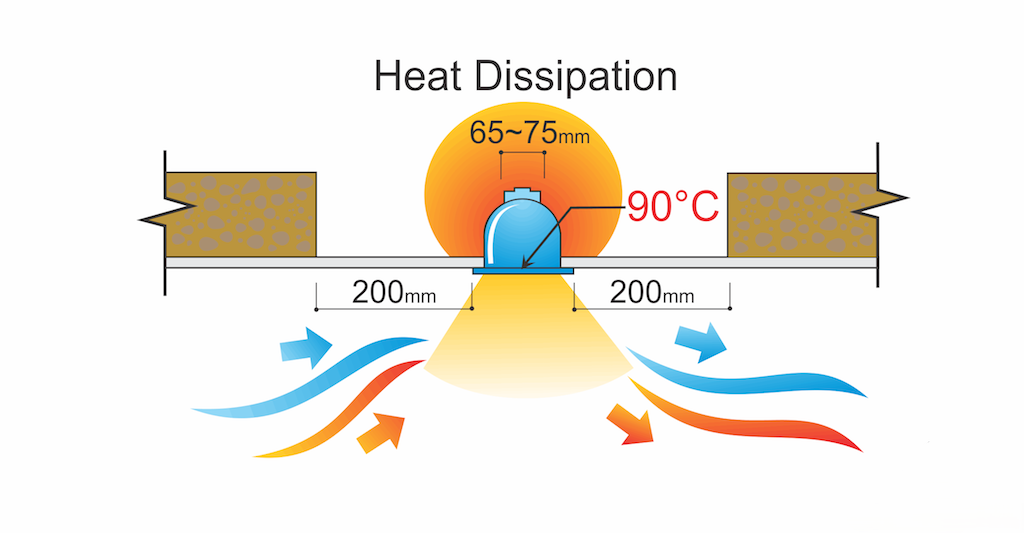

Fixed head fitting with no enclosure reaches 90˚C at the plasterboard (this is the limit for compliance to AS/NZS 5110). In order to keep this downlight cover at this temperature, the compliant barrier would need to be very well ventilated.

Halogen Globes reach extreme temperatures of 350˚C + and with a fixed head fitting can reach 90˚C without an enclosure. Fixed head fittings may benefit your home’s energy efficiency due to reduced air leakage rates compared to a gimble fitting, but they are uncoverable and thus require the 200mm insulation clearance stipulated in AS/NZS 60598.

Because these fittings can be installed with 50W Halogen Globes, they must be tested with 50W Globes, even though the GU10 Fitting may be sold as an LED Fitting. Beware to check that these fittings are labelled with AS/NZS5110 before thinking about submerging them in insulation. (Again, GU10 LED’s need to be tested with GU10 50W Halogen; otherwise, they don’t comply with AS/NZS 5110).

These types of fittings are extremely restrictive to cover and insulate due to the ability to retrofit them with Halogen type globes and should be avoided for new homes. It is critical in case your house is sold to someone who isn’t aware of the difference between Halogen and LED’s and undertakes replacing an LED with a halogen globe.

2. MR16 Fitting with a Gimble fitting and LED Control Gear (82mm + Cutout)

Status: Coverable

Compared to a Fixed fitting, a gimble has significantly reduced temperatures at the plasterboard when installed with halogen Lighting.

3. LED Full Fitting with LED Control Gear built into Fitting. (No GU10 no MR16)

Status: Coverable

LED fittings cannot be retrofitted with a halogen globe

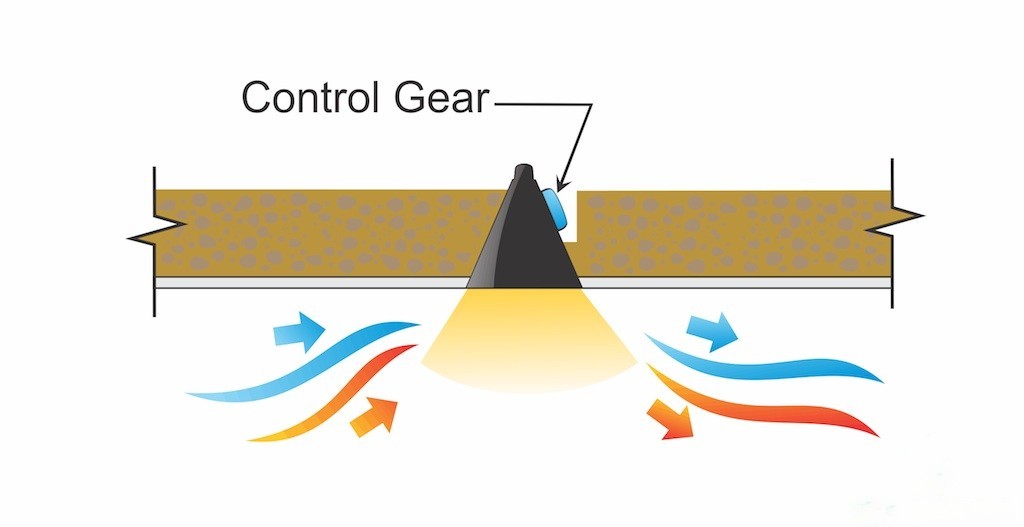

4. MR16 Fitting with LED Control Gear

Status: Coverable

LED MR16 Fitting cannot be retrofitted with a Halogen Globe due to the use of an LED Driver

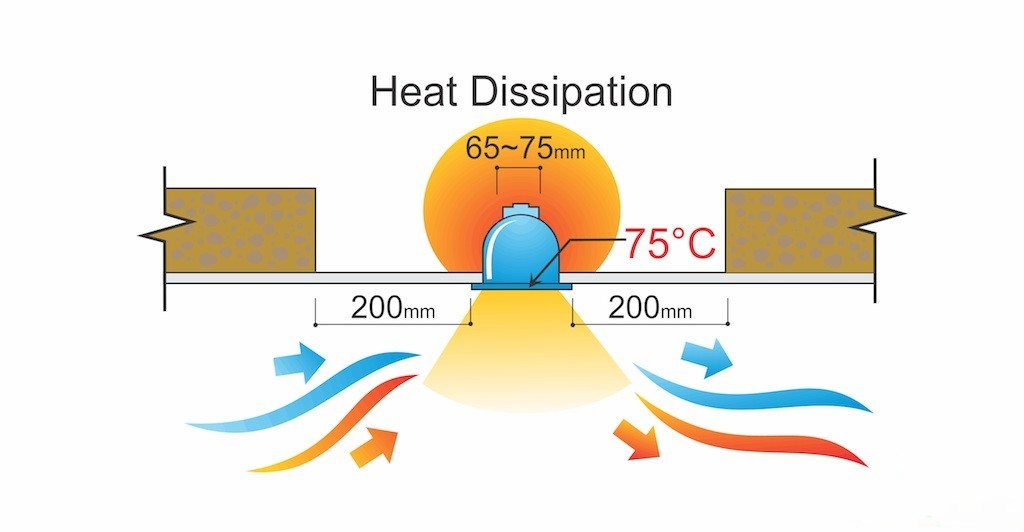

The Small Basic Downlight Covers are capable of complying to AS/NZS5110 for energy efficiency, sound proofing and with an up to 2 hour fire rating.

Benefits for covering LED’s

Loft area temperatures can get to temperatures of 70˚C. LED’s that are designed to be enclosed in a cover and ventilate with cooler living area air can benefit from an airtight barrier.

Building envelope extension in summer protects the LED from excess temperatures

Covering an LED downlight with a quality downlight cover can save considerable money on heating and cooling costs, but don’t forget about keeping control gear safe and out of the way of insulation. Efficiency Matrix downlight covers have a built-in loop for cable tying control gear.

LED downlight fittings installed with a building envelope extension (Recessed Lighting Barrier AS/NZS 5110)